Free tool helps manufacturers map where COVID-19 impacts supply chain

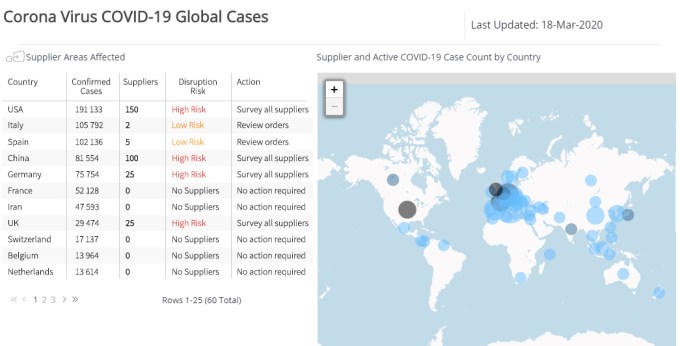

Assent Compliance, a company that helps large manufacturers like GE and Rolls Royce manage complex supply chains through an online data exchange, announced a new tool this week that lets any company, whether they’re a customer or not, upload bills of materials and see on a map where COVID-19 is having an impact on their supply chain.

Company co-founder Matt Whitteker, says the Ottawa startup focuses on supply chain data management, which means it has the data and the tooling to develop a data-driven supply chain map based on WHO data identifying COVID hotspots. He believes that his is the only company to have done this.

“We’re the only ones that have taken supply chain data and applied it to this particular pandemic. And it’s something that’s really native to our platform. We have all that data on hand — we have location data for suppliers. So it’s just a matter of applying that with third-party data sources (like the WHO data), and then extracting valuable business intelligence from it,” he said.

If you want to participate, you simply go to the company website and fill out a form. A customer success employee will contact you and walk you through the process of uploading your data to the platform. Once they have your data, they generate a map showing the parts of the world where your supply chain is most likely to be disrupted, identifying the level of risk based on your individual data.

The company captures supply chain data as part of the act of doing business with 1,000 customers and 500,000 suppliers currently on their platform. “When companies are manufacturing products they have what’s called a bill of materials, kind of like a recipe. And companies upload their bill of materials that basically outlines all their parts, components and commodities, and who they get them from, which basically represents their supply chain,” Whitteker explained.

After the company uploads the bill of materials, Assent opens a portal for the companies to exchange data, which might be tax forms, proof of sourcing or any kind of information and documentation the manufacturer needs to comply with legal and regulatory rules around procurement of a given part.

They decided to start building the COVID-19 map application when they recognized that this was going to have the biggest supply chain disruption the world has seen since World War II. It took about a month to build it. It went into beta last week with customers and over 350 signed up in the first two hours. This week, they made the tool generally available to anyone, even non-customers, for free.

The company was founded in 2016 and has raised $220 million, according to Whitteker.

Powered by WPeMatico